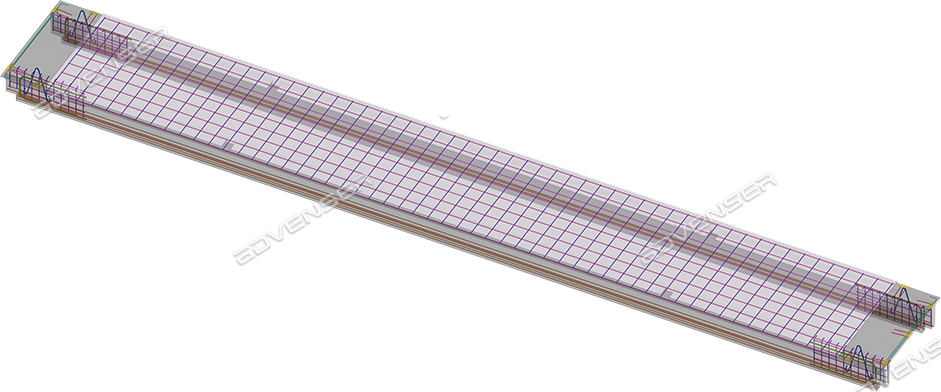

Double Tee Slab Detailing

Overview

Double Tee slab is a load bearing member that is fabricated by connecting two single Tee beams. They offer the advantages of long spans and high load carrying capabilities. Like other precast elements, they are also manufactured in a protected shelter with controlled curing. We provide expert Double Tee detailing and 3D modeling services for precast manufacturers and contractors, which help them with accurate fabrication and erection. Along with Double Tee shop drawings, we offer quantity take-offs and CNC files for automated production.

In recent years, we have completed projects for various diverse companies, predominantly in Australia, the USA, the UK, and other regions, solidifying our reputation for providing reliable BIM services.

Our Services

Precast Revit Families

Anchor Layout Drawings

Piece Drawings

Hardware Details

Architectural Precast Shop & Erection Drawings

Anchor Bolt Details, Connection Details

Production Drawings

Material Take off

Anchor Setting or Contractor’s Setting Drawings

Our Expertise in Double Tee Slab Detailing

Parking Garages

Office Buildings and Commercial Buildings

Factories and Industrial Buildings

Gymnasiums and Indoor Pool Areas

We have highly established precast manufacturer companies from Australia, USA and Canada amongst our clientele with whom we have had long term business association. Our in-house team of Double Tee precast detailing team consists of a group expert professionals that understand the basics of prefabricated constructions. All team members are highly experienced and well-trained in all the leading precast detailing platforms. We possess years of experience in Double Tee slab detailing projects using Tekla, Revit and AutoCAD.

Our precast detailing teams utilize 3D BIM modeling for preparing the Double Tee 2D Shop drawings and erection drawings.