The construction industry is rapidly changing as new technologies continue to be developed and implemented. One of the most exciting technologies is digital detailing, which is now being used in precast detailing to improve efficiency in construction. Digital detailing technologies are revolutionizing the precast detailing process, making it more efficient and accurate. 3D modeling and BIM (Building Information Modeling) software allow for a more precise and coordinated approach to detailing, resulting in fewer errors and less rework. These technologies also enable precast detailers to work more collaboratively with other construction team members, further improving accuracy and efficiency.

Introduction to Digital Detailing Technologies

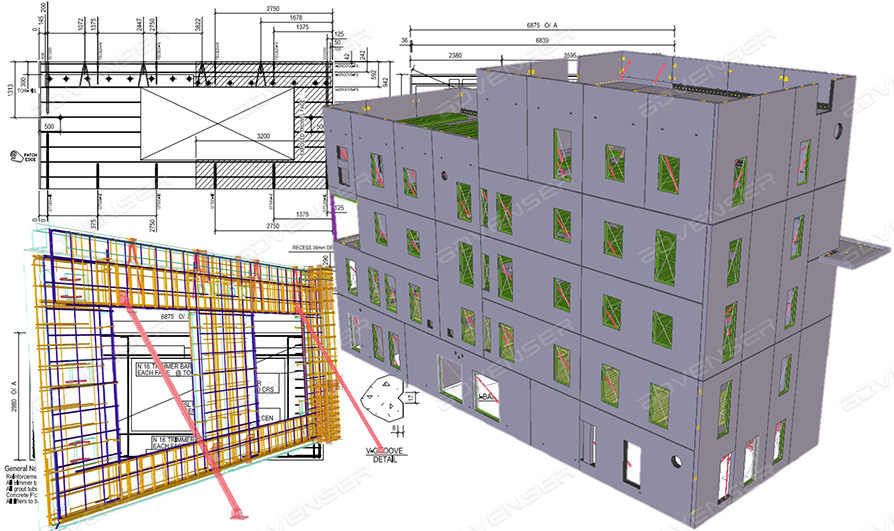

Digital detailing technologies are defined as any technology that enables you to manipulate images or models in real time. This includes everything from shop drawings, 3D modeling and computer-aided engineering (CAD) software to mobile applications and even virtual reality headsets. As technology advances, more and more details can be added to these images or models, allowing for a level of accuracy and detail never before possible.

Improved Construction Efficiency and Precision by Utilizing Digital Detailing Technologies!

Precast construction is a rapidly growing industry that has the potential to revolutionize the way buildings are constructed. By using digital detailing technologies, builders can save time and money while achieving improved structural integrity and safety. In this blog, we will explore some of the benefits of digital detailing technologies in precast construction and discuss how they can be used to improve efficiency and precision in the construction process. One of the biggest advantages of utilizing digital detailing technologies over traditional designing is quick data entry and the development of 3D models in the construction process. With digital tools, builders can quickly input information about a project, such as dimensions, materials specifications, etc. This allows for faster communication between various stakeholders involved in a construction project and more accurate structural design.

Benefits of Digital Detailing for Precast Construction

New technological advancements

Precast construction is an ever-growing industry that is experiencing rapid growth. One of the reasons for this is the fact that digital detailing has become a key part of the process.

Improved accuracy

First and foremost, digital detailing improves accuracy and efficiency in drawing production. By eliminating physical drawings, you reduce the amount of time needed to produce them and also reduce the chances of human error. This means that you can produce more accurate drawings faster, which leads to faster project completion times and reduced costs.

Flexibility

Digital detailing gives stakeholders more flexibility in how they share their drawings with other team members. Rather than having to send hard copies around manually, everyone can access them securely through a computer or tablet device. This increases coordination among teams as everyone can work together more effectively to achieve common goals – all without making any mistakes!

Eliminates the need for physical drawings

Digital detailing eliminates the need for physical drawings, which in turn speeds up the process and reduces costs.

Need ewer physical resources

Another advantage of digital detailing is cost saving through faster detailing proc. By working with detailed drawings instead of paper versions, you can save on printing costs as well as on labor required to complete the task. Additionally, by using automated processes such as 3D rendering or CAD software, you can speed up the task even further without sacrificing quality or accuracy. In short, digital detailing allows you to complete your precast construction project with fewer physical resources than before while still maintaining high levels of detail and quality control.

Real time project monitoring

Digital detailing also allows for better tracking and monitoring of project progress in real time so that stakeholders are always aware of where they stand and what needs to be done next – no matter where they are in the process!